The trigger was removed from its assembly and a hole was simply drilled and tapped through the trigger so that a 6 X 32 set screw could be screwed through it. The hole was drilled so that the screw resides just above the trigger spring and at a like angle as the spring. This position places the screw as far out of sight as possible and drives the screw directly onto the inside face of trigger guard when the trigger is depressed.

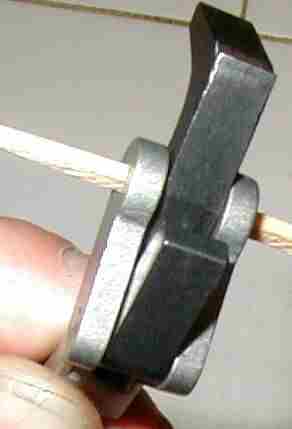

The set screw was fashioned by cutting the head off a 1/2 inch 6 X 32 hex screw and cutting a screw driver slot in its place. It was then shortened so that it would not protrude from the trigger face when adjusted. The screw was then re-blued using a good cold blue solution.

After field testing to determine the optimum adjustment (zero over-travel without interfering with trigger pull) the screw will be locked in place with a thread lock; a drop of super glue, finger nail polish or the like on the back side of trigger.